It’s a call that no retailer ever wants to get—the Occupational Safety and Health Administration (OSHA) is on-site for a surprise safety inspection. For Scott Jerousek, owner of Farm & Home Hardware, which operates two stores in north central Ohio, with a third opening by the end of the year, it was more of a wake-up call that led to the development of a comprehensive safety program for the business and a “safety first” culture among his 130 employees.

“I’m out of town and get a call from the office manager at our Ashland store who says there is an OSHA inspector on-site for a surprise visit,” Jerousek says. “Of course, my first thought was, ‘Who turned us in?’”

Jerousek suspected a disgruntled employee they had let go several days prior was responsible. But he says the focus quickly shifted to the nature of the violations and what measures they needed to fix. In this case, it was related to several forklift safety violations.

It started in the warehouse of his Ashland, Ohio, store where employees were using forklifts with a platform attached to get appliances off the upper racks. Employees would take a forklift up 20 feet high and were stepping off and pulling appliances onto it, which is something Jerousek says he knew they shouldn’t be doing and were lucky no one was ever hurt.

“You always plan on making changes tomorrow or next week,” Jerousek says. “Then more pressing issues arise, and the safety program upgrades are put off.”

Ironically, he purchased a clamp truck for this specific purpose six months prior but wasn’t using it yet.

“That was the big violation we received,” he says. “Whenever you go higher than 4 feet, you must be strapped in. We had safety harnesses, but we weren’t making sure everyone was trained on how to properly use them and weren’t documenting training.”

The other OSHA citation they received was also related to forklift safety. In this case it was a Chemical Hazard Communication Standard (HAZCOM) violation where employees were topping off batteries in forklifts with water without wearing proper personal protection equipment (PPE).

Todd Jensen, director of OSHA’s Toledo Area Office, which oversees the region where Jerousek’s stores are located, says forklift violations are the top infraction he sees in the business classification that includes hardware stores, home centers, lumberyards and paint stores.

“In northwest Ohio, we’ve probably had five or six forklift violations at these types of stores since the first of the year,” Jensen says. “And the one thing that’s common between them all is they all need to improve their forklift safety training.”

The Negotiation Process

As an enforcement agency, Jensen says OSHA doesn’t give any free passes after a citation is issued. And the violations that Farm & Home Hardware was cited for amounted to $40,000 in fines, the starting point for negotiations. From there, a meeting was scheduled to discuss the citations and outline an abatement plan.

As an area director for OSHA, Jensen says he can lower penalty amounts based on the willingness of the employer to cooperate, fixing what’s wrong and thoroughly documenting it. In the case of the fines at Farm & Home Hardware, the initial $40,000 fine was lowered to $18,000, the maximum amount it could be reduced. Farm & Home Hardware also agreed to a six-month payment plan.

After a violation of this nature, Jensen says he wants to see an abatement process put in place. Jerousek relied on Daryll Mauder, his department manager for delivery, install and warehouse, to set up the abatement process and oversee all company safety initiatives. He says the timing was also good because developing a safety program would also serve as Mauder’s semester project for the North American Hardware and Paint Association’s (NHPA) Retail Management Certification Program.

The Abatement Plan

OSHA reduced the fine from the maximum amount thanks to Mauder’s swift actions to improve safety after the citation. He implemented a forklift training protocol, obtained proper OSHA certifications and contracted preventative forklift maintenance through his manufacturer, which includes regular battery checks, preventing his employees from performing this maintenance themselves.

The next initiative was to make sure records for all safety training were being properly logged. This required Mauder to take a series of classes, including OSHA 300 Recordkeeping, a 10-hour, online certification.

The next initiative was to make sure records for all safety training were being properly logged. This required Mauder to take a series of classes, including OSHA 300 Recordkeeping, a 10-hour, online certification.

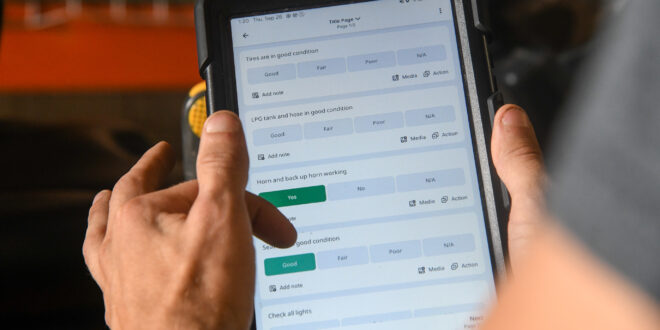

“Now, instead of reacting to everything, we are being proactive,” he says. “That’s the mindset Scott and I want to have moving forward for Farm & Home Hardware. Every morning at the start of the shift, we are using an app called Safety Culture, which helps us keep all records current, going above and beyond what OSHA requires of us.”

The app takes the user through a series of questions, with the ability to take pictures and include notes related to the inspection. It requires staff members to physically inspect components like overhead guards, lift cages, tires, tanks and hoses, working horns and seat belts, so they can document any physical damage that would be detrimental to its operation.

“We conduct these inspections every day to make sure our equipment is safe to operate, which will allow us to take better care of our customers,” Mauder says.

The training also extends to analyzing customers’ vehicles for safety purposes.

“We load a lot of bulk items, and sometimes we’re loading up a truck that maybe just came off the farm and it doesn’t look road worthy,” he says. “Our motto is ‘Once we touch it, we own it,’ and we take a lot of pride in that. The only setback to our customers is that we are slowing down to make sure we are doing our jobs safely, instead of hoping for the best.”

Jerousek says their comprehensive eff orts to start training employees on forklift safety and the OSHA certifications Mauder obtained immediately following the citation provided the confidence OSHA needed to lower the fine.

“Daryll did a great job showing all of the training we implemented, with daily walk-arounds for each vehicle, to make sure everything is in order,” he says. “We also provided documentation of a service contract with our tow motor provider to maintain the batteries and rest of the equipment.”

Next Steps

Between the 20 hours Mauder has logged for his forklift certifications, the standard operating procedures (SOPs) developed and the safety training being implemented for everyone, abatement has required a lot of time. But it’s something Mauder wants to complete. His next step is a 30-hour OSHA program covering emergency preparedness, including fi re escape, tornado safety and other emergency action plans for staff members and customers.

The safety training has also extended to other vehicles owned by the company. Jerousek says every vehicle owned by the company now has GPS trackers, and the plan is to add cameras to see idle time and analyze the best routing for deliveries.

“We have 10 to 15 trucks on the road any given day. Those jobs carry with them the highest possibility for liability. Due to that we focus on controlling as many factors as possible to ensure the safety of our team,” Jerousek says.

Now the company has a regular protocol for safety checks of parts like turn signals and brakes to ensure vehicle safety when out for deliveries or during store transfers. Other miscellaneous safety training that has been added to the program at Farm & Home Hardware includes electrical safety training to prevent fires and having guards on all power tools and machines used by the business.

Jensen says the most common electrical-related citations are easy fixes, including not using extension cords with missing ground prongs and not plugging power strips into one another. When becoming OSHA compliant, Jerousek says there is a greater burden placed on smaller, independently owned operations because they often don’t have the comprehensive safety and training resources that larger organizations utilize.

“In OSHA’s eyes, everyone is the same, whether it’s our business with over 100 team members, a typical hardware store with 10 people or Ford Motor with hundreds of thousands of employees,” he says. “All of us must adhere to the same rules and regulations, and OSHA requires the same safety standards from everyone.”

Jensen says OSHA could do a better job providing information to independent retailers, as he says national chains like Home Depot and Lowe’s have entire teams dedicated to safety and compliance.

“We could do a better job getting information out to smaller retailers on what is required for specific employers, but we just don’t have the resources to target every employer in the U.S.,” Jensen says. “So, what we do is put it back in the employer’s lap with information and resources on our website.”

Savings Add Up

An added bonus to the safety program now in place at Farm & Home Hardware is it should help reduce the number of workman’s comp claims recorded each year, which is typically four or five, Jerousek says.

“They are mostly related to employees getting cut in various ways, or on the appliance side of the business, such as foot and back injuries from lifting heavy items and putting them in tight areas,” he says.

The greater focus on safety also reduces the number of damage claims when installing appliances in customers’ homes. To help train installers, Mauder says they are building a training center at one of their warehouses for delivery and installation team members, where they can get hands-on experience before they go to someone’s house.

The retailer has also developed a safety bonus program using manufacturer spiff dollars that are now divided up three ways, after any damages are paid out to customers.

“We are now utilizing those dollars to fund a pool where our sales team, delivery drivers and service technicians all receive a percentage of the money,” Jerousek says. “We pay for customer damage claims and employee issues first, then divide the remainder up into sizable bonuses twice a year. This has helped to give every member of the team individual ownership of their financial futures, while also creating a culture of accountability.”

OSHA as a Consultant

Jerousek says his experience taught him that OSHA is a great resource to help retailers operate safer stores. If an owner wants OSHA to visit their store to do a consultation, OSHA will not fine them for what they find but will want them to fix any violations.

“Some larger retailers I know spend a lot of money hiring third-party companies to help with safety prevention, but most retailers don’t have the resources to utilize these professional services,” Jerousek says. “So, they try to figure it out themselves or reach out to others in the industry, but the OSHA regulations are difficult to fully understand. When you are in a situation, the last thing you want to do is to reach out directly to OSHA and give them the opportunity to find more issues. But we took the jump and spoke directly with our local OSHA office to ask for guidance. What we received was an honest, empathetic discussion that helped us to fully understand the safety rules we need to adhere to.”

Jensen says consultations are free, with no strings (or fines) attached.

“I can guarantee you, in Ohio, if you call an OSHA office with a question, we are not going to do an inspection just because you call; that would defeat our purpose,” he says. “We’re not going to ask you who you are or where you’re located. We don’t have the resources to send a compliance officer out to everyone who calls.”

Jensen adds that the lack of resources in most OSHA regional offices throughout the country also prevents them from conducting follow-up inspections in most cases.

“If the employer is willing to fix what’s wrong, that’s usually enough for us. We will do follow-up inspections when we don’t think the employer is going to follow through or is fixing the problem temporarily to get us off their back,” he says. “But the likelihood of a follow-up is minuscule.”

Staying Focused on Safety

The events that led to developing the safety program at Farm & Home Hardware have changed the company’s mindset around safety in a positive way. But Jerousek says it is all for naught if they don’t remain laser focused on safety moving forward.

“As a result of everything we have been through this year, we now have a full-fledged safety program, whereas before, it was just a forklift safety program,” he says. “We have grown from one to two stores in the past several years, and now we’re adding a third. We just got so busy that we didn’t focus on safety like we should have.”

Overall, he says the experience dealing with OSHA was very positive, minus the fine, and that everyone they worked with was highly professional and helpful.

“We get up every morning, turn on the lights and try to make a positive impact on our communities with our teams,” Jerousek says. “Somewhere in there we need to allot time for safety.”

Forklift Safety Training Requirements

Proper forklift safety training generally includes two parts. First is the online piece that is offered through various service providers, including J.J. Keller, which is available through NHPA.

The second part involves one-on-one operator evaluations. When conducting these evaluations, Jensen says it needs to include conditions that forklift operators are going to face in the workplace.

“You just don’t want them driving in the back room, lifting pallets up on shelves, and that’s it,” he says. “When they’re going outside and getting a pallet of rock salt in a dirt lot with potholes, you need to evaluate how they perform in those types of situations, too.”

Jensen also advised retailers not to rely on anyone else’s forklift training for new hires.

“If someone says they have training from another employer, always double down and do it again, because you’re relying on someone outside of your company to make sure that employees and customers are safe in your place of business.”

Top 5 OSHA Violations for Home Improvement Stores

According to Todd Jensen, director of the OSHA Toledo Area Office, the most common infractions for independent home improvement retailers include:

- Forklift Safety Training. The lack of a formal forklift safety training program is the top OSHA violation among home improvement retail stores, including the daily inspections that need to be done for each unit.

- Chemical HAZCOM Training. There are many chemicals used in hardware and paint stores, and anything other than water is going to be considered a hazardous chemical. Be sure team members are trained on the health effects and proper procedures for paint spills and other chemicals that will likely spill at some point and need to be cleaned up.

- General Duty Clause. These infractions many times include propane filling operations, where the setup isn’t proper or employers aren’t wearing gloves and base shields when they’re filling tanks. Or, if there are devices being used to make adapters for tanks that aren’t approved. “We have seen plenty of systems that have been completely rigged up to make them work,” says Jensen. “And it’s just not safe.”

- Machine Guarding. Most retailers have shop tools, such as pipe threading machines or a band saw or bench grinder in the back room, and this equipment has to be properly guarded and shielded.

- Record Keeping. If you have more than 10 employees, you must keep OSHA 300 injury logs. Jensen says oftentimes retailers just don’t fi ll them out properly.

Hardware Retailing The Industry's Source for Insights and Information

Hardware Retailing The Industry's Source for Insights and Information