Recently, I was analyzing our stores and began looking in-depth at our inventory. While I would like to think that we do an above-average job at maintaining our databases, cycle counts, etc., I began to question how actively we truly manage our inventory.

I wondered if we were actually in control of our assortments or if we were simply maintaining them.

As I began to analyze our processes, I looked at which products were selling and which weren’t. While I could write about the successes of many of these items, I wanted to take an opportunity to focus on what I consider to be the more important part of the equation—the products that aren’t selling and what to do with them.

An Analytical Approach

If you consider your store and all of the space in it as an opportunity to potentially sell something, then what is the cost of the items that do not sell?

Certainly there are items that do not sell for months or even possibly years (walk over to your brass fittings section if you need an example). But despite the lackluster sales of those items, we, as retailers, are expected to have certain slow-moving items in stock. But what about the items that don’t sell that we’re not expected to have?

Think about your inventory and the bad buys you or your staff have made over the years, or those precious items you fell in love with on the show floor or vendors talked you into that now reside on one of your shelves.

Letting Go

Remember that your pay to heat, light, clean and move product around you valuable real estate. Now, you may look at your current product assortments and tell yourself, “Someone will need that someday,” or “I paid good money for that and it’s still worth something to someone.” But the reality is that every day you refuse to face the fact that you made a bad buy is another day lost to putting those resources (cash and shelf space) to work on something that will make a profit.

Consider the opportunity cost. If you are unfamiliar with the term, opportunity cost is defined as the cost of an alternative that must be forgone in order to pursue a certain action. Put another way, it’s the benefits you could have received by taking alternative actions.

In this case, opportunity cost refers to the fact that you have a limited amount of resources and the longer you hold onto and fail to get rid of dead inventory, the more it costs you over time in lost opportunities of items you could be selling. Gross margin is, in fact, a perishable item.

From My Perspective

With this in mind, as I researched my own failures as a buyer, I considered what a proper course of action would be to set my staff on track to rectify my once-glorious acquisitions. I boiled it down to three basic steps:

Identify—First, record anything in inventory not perceived as a requirement for a hardware store to carry that has had zero sales for a set period of time (I chose 18 months).

Liquidate—Come up with a plan for how much of a reduction you think it would take to get someone to buy those products or what the cost

was to simply throw away or recycle the items.

Replace—Exchange slow-movers with new inventory or categories that need rounding out.

Although easy to identify in three steps, the actual execution of this plan is somewhat more complicated.

Identify

As far as identification, I found using my POS system and downloading the store’s inventory into a viewer or Excel spreadsheet was the fastest way to run various queries, based on my earlier-stated criteria.

By taking cross-sections such as “quantity on hand greater than zero,” “date of last sale older than 18 months,” “location,” etc., I was able to quickly narrow down a group of 30,000 SKUs to a couple thousand.

From there, I worked the list line by line, weeding out my brass fittings and other obscure items I absolutely need to carry to only those that were the bad buys. This same process could be done in a non-POS store by walking your aisles and simply making a list of items based on the age of the tags.

Either way, as long as you are brutally honest with yourself and evaluate your findings objectively as an investor rather than a store owner, you should come up with a substantial list of items are ready for step two.

Liquidate

When it comes to closing inventory out, there are two things you need to consider more than anything: placement and price.

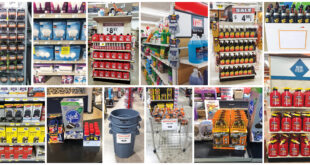

The items you’ve selected have already proven themselves to be dogs, so don’t waste your time reducing them by 10 percent and moving them to another shelf in your store. Drop the price by half and throw them on an endcap (if you have a large quantity), or set up a closeout table at the front of the store where every person who walks in the door has to look at the items.

Although I have seen stores that dedicate linear shelf space to closeout (I have tried this myself), I firmly believe it compromises the idea of opportunity cost discussed earlier. It is much more effective to close it out in the front of the store than to bury it in a random 4-foot section (not to mention that it makes for a terrible-looking set that is also harmful to your store’s image).

With respect to price, you will only have a limited opportunity to get your customers to stop and look at your closeouts.

If you fail to price the product at a price that will move it the first time, odds are you will be throwing it in the dumpster later.

Last, do not set up your closeout table and leave it out indefinitely. If you dramatically reduce the price and every one of your customers has seen it and still have not committed to buying, then either donate these products (to an organization that can actually use them) or throw them away.

Inventory write-downs are still considered a business expense that you can at the very least write off on your taxes, so keep good records of what you purge from your inventory and be sure to give the list to your accountant at the end of the year.

Replace

The third and final step in removing dead inventory is replacement. The only thing worse than old inventory on your shelf is an empty shelf, as you are still suffering opportunity costs as well as hurting the image of your store.

Prior to eliminating inventory, there needs to be a plan on what you are going to refill that spot with. You may find you will be forced to reset an entire section in your store. I recommend using your distributor in this step by having your company rep identify categories/SKUs other stores in your region do well with that you are missing in your product mix. Your company reps are more than willing to help you with these resets, as it is in their best interest to help you increase sales and inventory turns.

Working the identification process just prior to buying shows is good for taking advantage of lower upfront costs and will help ease the pain of eliminating inventory. Be aware of your cash position through this process, as if you find you have a lot of dead inventory, you may either want to finance your changes or take it in smaller bites over a couple of years so as not to jeopardize your cash flow.

Steps two and three could be done in either order, depending on whether you plan to use your cash from liquidation to purchase new inventory or simply to buy the inventory and worry about recovering dollars out of the old stock later.

Facing Reality

While admitting you are not the industry’s greatest buyer may be a bruise to the ego, it is critical you remember you are running a business and that inventory may very well be the largest asset you manage on a day-to-day basis.

To ignore your inventory (particularly bad inventory) not only makes you less profitable due to lost sales but can also hurt the resale of your business when you retire. No one is going to pay full price for a store full of bad inventory.

By cleaning up dead SKUs as part of an annual routine, you will keep your store looking fresh, do a better job of meeting your customers’ needs and be more profitable, both in the short and long run.

Hardware Retailing The Industry's Source for Insights and Information

Hardware Retailing The Industry's Source for Insights and Information