Lowe’s plans to change space travel with its latest tech project—and that’s not a far-off fantasy.

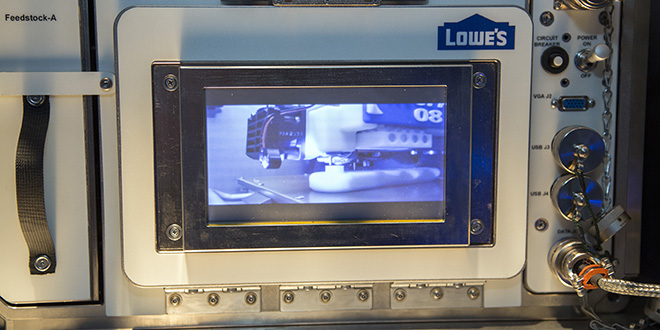

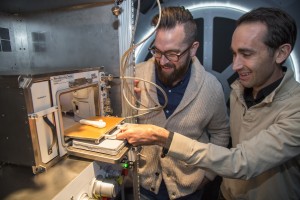

The giant retailer is slated to launch a commercial 3-D printer to the International Space Station in early 2016, taking manufacturing off the Earth. The goal is to enable astronauts to manufacture tools and other needed items as necessary.

“For the first time, astronauts can now manufacture what they need, when they need it, in space,” says Jason Dunn, chief technology officer and co-founder of Made In Space, Lowe’s partner in the project. “And now with the launch of the permanent additive manufacturing facility to the (International Space Station), we are enabling humanity to manufacture things off the planet.”

The project is just the beginning of Lowe’s work with Made In Space, according to Kyle Nel, executive director of Lowe’s Innovation Labs, an arm of the home improvement company that is dedicated to developing new technology.

“Lowe’s and Made in Space share a vision of how 3-D printing can revolutionize retail and home improvement, while also changing the way astronauts work in space,” Nel says.

About 30 percent of the International Space Station’s parts could be made and replaced with a 3-D printer, saving money and time, according to Lowe’s Innovation Labs.

Fortune magazine describes the space printing process with a hypothetical project:

“Let’s say a ratchet goes missing and needs to be replaced. A design team in California will sketch a 3D model, print it, and get NASA approval. The agency’s team on Earth will then sign off, and the ratchet will be printed in space. That process would take about two hours, though for smaller, simpler projects, it could take less time.”

Hardware Retailing The Industry's Source for Insights and Information

Hardware Retailing The Industry's Source for Insights and Information